TeletypeASR-33

If the collective noun for printers is a problem, then a group of teleprinters must be a crisis. In late 2021, I went from owning one teleprinter, an Olivetti Te-318, to four, with the acquisition of a Digital Decwriter II and two Teletype Model 33 ASRs. I'll document my repair and use of the Teletype machines here.

Comparative teleprinter studies

The Teletype Model 33 ASR (or ASR-33) is the archetypal computer hardcopy terminal. As a (relatively) inexpensive terminal with the ability to store and retrieve information by paper punch tape, the ASR-33 was a user interface in both the burgeoning personal computer movement and the development of time-sharing systems in the 1970's. Thus, we have the famous photograph of Ken Thompson and Dennis Ritchie at an ASR-33 in front of the Bell Labs PDP-11 during the development of Unix, and the story of Paul Allen flying to meet Ed Roberts in Albuquerque, NM -- crossing the country carrying a punch tape copy of what would become Microsoft BASIC, written together with Bill Gates. When he arrived, Allen read the tape into a Model 33 connected to Ed Robert's new MITS Altair 8800. The Teletype survives to this day as a terminal description on many Unix and Unix-like operating systems and /dev/tty devices.

One of the reasons I wanted to restore an ASR-33 are the differences between it and the Olivetti TE-318 that I have in my collection. Both machines were later products in a long line of teleprinter technologies and devices dating to the early 20th century. It turns out that the Model 33 relies heavily on electromechanics compared to the Olivetti. Although both teleprinters are essentially mechanical devices---operating on the same principle of receiving a bitstream of electrical impulses and converting them to mechanical action through the movement of an electromagnet (essentially telegraphy)---the ASR-33 accomplishes more functions using electrical systems. Mainly, the differences lie in the keyboard and reader that are responsible for sending a bitstream. The reception systems work largely on the same mechanical principles, with subtle differences in their implementation.

Unlike the Olivetti, the ASR-33 uses electrical contacts in the keyboard and paper tape reader to send ASCII codes and characters. The mechanical keyboard mechanisms ultimately move wires between contacts that map a matrix of keypresses to 7-bit ASCII (with even parity), including control and shift functions. These electrical connections propagate to the distributor mechanism, which, by a rotating electrical contact, serializes the 8-bit signal. In the Olivetti, keypresses and codes are conveyed entirely mechanically across the machine. The serializer in the Olivetti ends up moving a blade up and down that opens and closes the circuit to generate the spaces and marks.

Here are images of the ASR-33 keyboard and the distributor:

Compare these with the mechanical serializer of the Olivetti:

Likewise, the ASR-33 punch tape reader uses sensing pins to make electrical contacts. A sensing pin moves up into the paper tape holes to generate marking bits, while the paper prevents the pin from closing and leads to a spacing (0) bit. Again, the Olivetti accomplishes this mechanically --- spring-loaded "feelers," similar to the ASR-33's sensing pins, push through the paper, moving an underlying lever, which begins the propagation of this tiny displacement across the machine. The mechanical amplification of the initial displacement is intriguing. The drive mechanisms between the readers are different, too. The ASR-33 advances punch tape using a ratchet driven by a separate solenoid magnet; the Olivetti's reader is coupled to the main rotating power shaft of the teleprinter though a helical gear. The differences in the overall engineering design between these machines contribute to the more compact size and lighter weight of the Teletype when compared to the Olivetti.

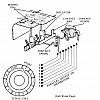

Below: Diagrams of the Olivetti and ASR-33 tape readers show their mechanical and electrical connections, respectively.

Below: An Olivetti Se-305 (5 bit baudot) tape reader and the ASR-33 reader. Note the entirely mechanical operation of the Olivetti, including the helical gear that drives it. The ASR-33 reader advances tape and the reader mechanisms by an electrically controlled solenoid.

Description of the ASR-33

I acquired two Model 33 machines on December 5, 2021: one complete and one incomplete. The incomplete model was stripped of its keyboard and is in poorer physical shape, with more grime and dirt. Neither of the machines had signs of small mammal homes when I received them, and corrosion is limited to a few isolated areas.

Unit 1 complete

Machine parts and components (complete ASR-33)

- MODEL 332D 5JF (on baseplate)

- Typing Unit - CODE UP837 MA

Serial number: 401102 (stamped into typing unit frame below functions unit bars on right)

Dremeled in side: MA1950

Sticker 1: REPAIRED Date 11 06 81 Number MA1950 By 43128

Sticker 2: DWG. (blank) REV (blank) ECO MA1950 03920012.905 - Reader - CODE UX801

- Punch - CODE UPE802 L

stamped in side: 817968 - Keyboard - CODE UK819DSM - SER. NO. 287628

- Power Unit, UCC-6 - CODE 693640

Unit 2 incomplete

Machine parts and components (incomplete ASR-33). This machine is missing its keyboard, but the typing unit has more features, including the line spacing option. I picked it up because I thought it might be handy to have a parts machine, but I could at least restore it to an "RO" (receive only) configuration without the keyboard.

Details to fill in:

- MODEL 33 (on baseplate)

- Typing Unit - CODE UP102/141/NU

Serial number: 323720 - Reader - CODE UX801

stamped in right side: 004837

Missing parts: start / stop / free lever; latch; latch release - Punch

- Power Unit (disassembled) - UCC-6

CODE 686542

Provenance

These machines were salvaged by Tim Colegrove, proprietor of the Byte Shop in Jamaica Plain, MA. Based on property tags, at least the first unit appears to have belonged to Honeywell. I purchased them from Tim and transported them by car back to my shop in early December 2021.

Restoration

It didn't take too long to get the first Model 33 up and running. Either it was in better shape, or my teleprinter repair skills are improving after three years of tty work in the retrolab.

State of the machine

Unit 1 was in relatively good shape, with all of the obvious parts accounted for, very little corrosion, and no mouse house remains. The fuse holders were all intact and the fuses good. As expected, it was coated with a solid layer of grime. The foam oil pad in the bottom, which is similar to the sound damping foam in the Olivetti, had thoroughly degraded and was flaking onto the greased and oiled components. Much of the oil and grease in the machine had become gum-like. Under these conditions, parts are often frozen or move more slowly than required for proper function. So, the first part of the restoration was to get the machine apart, cleaned up, and moving again.

Major repairs

The Model 33 is modular and disassembles relatively easily. Compared to the Olivetti, which relies solely on mechanical linkages, the electrical connections of the reader and keyboard make them straightforward to separate out. The typing unit rests in the base on four rubber gaskets. After disconnecting the keyboard, the typing unit, attached punch, power supply unit, and reader all lift out of the base. I removed the foam and cleaned up the oil and debris, then began wiping down the typing unit.

I started to work on the keyboard. Typical for the Model 33, the retaining clips (e-clips) were missing on the sides of the keyboard, which caused it to start springing apart when I removed it from the case. I replaced the clips, but I also kept the sides held by a clamp. I lubricated the keyboard and kept working it to loosen the mechanisms. The fussy bit getting the keyboard back together was getting the universal lever in the correct position relative to the nonrepeat lever and latch lever. After this, the machine was chattering in LOCAL and LINE mode. It turned out that the trip lever (183098) that is released from the answer back solenoid (300M) was below the latch mechanism (armature extension 185775 + armature 180844). I discovered this after looking at the spare typing unit. I set it above the latch mechanism and this fixed the chattering distributor. The keyboard, distributor, and selector responded as expected in local mode. Some characters were even correct, but there was no LF or CR response yet. I scoped the distributor output. The keyboard was sending the correct characters, so problems were in the reception and printing mechanisms.

I removed the print head in order to have better access to the selector solenoid and push lever mechanisms. I repositioned the selector armature by adjusting loosening the mounting screws. After, this I was able to successfully receive bytes. It seems that the armature was missing the first few selector levers. Using the punch, I verified the reception by typing U and * in local. (The bit patterns, with even parity, are repeating 1's and 0's.) I also typed out a tweet and sent it via the Olivetti reader. Success!

Next I turned to the print head. The mechanism was locked up with solidified grease and required cleaning and lubrication. When I first put the print head back in, I stopped getting good reception. Of course, when I investigated the print bars (by removing the print carriage again), I snagged and accidentally released the spring on the left-most function lever. As I pushed on the function lever itself, it fell out. I had to pull the entire typing unit from the tray and get it on its side, careful not to rest its weight on the distributor. I seemed to get the function bar back in. I got everything back in the case, but I had to readjust the magnet again. After two or three more attempts, I finally got the print head installed and working. Surprisingly, I got reception to work and the printer to print! Everything except line feed worked at this point. The frozen line feed was unlocked using the adjustment screw behind the line feed pawl. I moved this down and back to give the pawl more space to recover. This enabled it to detach from the ratchet mechanism.

Aside from minor adjustments to the reception (which seems fairly robust now, several months later), my final repair was to get the reader working. It actually ran when triggered, but the tape didn't feed. It turned out that the solenoid driving the tape feed wasn't getting power. The reader power board that drives the solenoid is a separate module in the power supply. The cause was a blown fuse (Bussmann AGC-3/4 AGC Series Fuse, Fast Acting, 3/4 Amp, 250V, Glass Tube, 1/4" x 1-1/4"). I ordered spares and blew through three of them before trying something different. It turned out that the C1 capacitor needed to be reformed. I did this by powering the machine on a variac and slowly (over the span of several hours) ramping up the voltage. Pulling out C1 and measuring the leakage current (at a lower voltage) indicated that it started to reform. After this step, the fuses stopped blowing and the reader solenoid activated as expected.

That's pretty much it -- mostly cleaning and a few tweaks and adjustments got the Model 33 in fairly reliable shape. The only remaining issues are that shift-1 ("!") seems to jam the keyboard frequently and the space bar still doesn't recover fully. I can't tell if the latter problem is due to poor lubrication, a weakening of the springs, or both (or something else out of alignment.) The Model 33 keyboard is not for the faint of heart. It feels pretty unstable -- ready to spring apart into thousands of pieces.

Here are a few pics of the restored Model 33, including a custom chad box and nameplate. The cover is significantly yellowed, but the sound -- the sound is so sweet. Chunka chunka chunka...

Documentation

Personal notes and sketches made during the restoration.

| File | Type | Size | Description |

|---|---|---|---|

| ASR33_Notes.pdf | 101M | Notes and sketches |